1. Propeller and tailshaft assembly, filling

of void spaces and sealing.

In a large number of fractured tailshaft

cases, there has been evidence that water had probably entered the propeller assembly

from the after end, in several cases this evidence has been indisputable. There

also has been evidence of detective seals at the forward end of the propeller

and of poor propeller and key fits. As a result of these reports a survey was

made of the procedures being followed in a number of representative shipyards

and this survey disclosed that in many yards, one or more of the details of assembly

were not being carried out as originally intended by the designers.

In view of the importance of a good

propeller assembly to the safety of the ship, and for large vessels, the problem

of large drydock availability and cost, the following noted should be carefully

studied. Each Surveyor shall check the exact procedure being followed in any

yard coming under his/her supervision. If the yard practice deviates from that

recommended in the notes, the subject shall be discussed with the proper

Shipyard Authorities with a view towards correcting the Yard practice. The experience

Surveyor will assist in the matter in every way possible.

a. A good fit of the propeller hub on the

shaft taper is essential. The number of reports being received stating that the

wheel tit was found slack indicates that considerably more attention needs to

be paid to securing a satisfactory tit. There shall be a uniformly good tit

over the whole of the taper, and it is necessary that the final fit be checked

with a light coaling of Prussian blue or similar compound. A slightly heavier

fit should be obtained on the big end.

b. The keyways in the hub and shaft shall

be checked to see that they are parallel to avoid any wedging action by the key

when the propeller is driven up.

c. The key shall fit snugly in both

propeller and shaft so that there will be no possibility of play al either side

of the key. A clearance of about 1/32 inch should be provided at the top of the

key.

d. It is considered inadvisable to use blue

compound, grease, oil or similar substances on the taper to facilitate driving

up the propeller; dry metal to metal contact gives a better grip between hub and

shaft.

e. In the final assembly, the propeller

shall be driven up beyond the mark al which an acceptable fit was obtained. The

amount will vary depending on the material of the hub and the degree of fit obtained.

For a solid bronze propeller a good average is about 6 thousandths on an inch

per Inch of shaft diameter, which would give about 3/32” for a 15 inch shaft and about 1/8" for a 20 inch

shaft.

After having secured a good fit of the

propeller hub on the shaft and a good key fit the primary object is to exclude

all salt air from the void spaces in the assembly and to prevent the access of sea

water,

f. Before the propeller nut is put on, the

recess formed at the small end of the taper by the overhanging propeller hub

should be packed with red lead or one of the corrosion-inhibiting products such

as Esso Rust Ban #324, Gulf No-Rust #1 or #3. It is extremely important to pack

this material solidly into the open space at the top of the key in the

propeller hub keyway so that it will act as a positive water stop and prevent any

possibility of water finding its way along the top of the key to the forward

end of the keyway, where the failures are occurring.

This practice is carried out in only a very

few yards. We feel that this should always be done as it places a positive

water stop exactly where it is most needed al the after end of the assembly. We

also feel that tack of this seal has contributed directly to the increase in

the number of shaft failures.

Red lead or other compound should not be

used where the nut bears on the hub as metal to metal contact is necessary.

g. The fairwater cone should be filled with

tallow or one of the above mentioned petroleum products.

Filling the fairwater cone with tallow is

not in itself a sufficiently positive means for excluding all water from the after

end of the assembly. There are several reasons why this is so. The joint between

the hub and the cone is seldom if ever light. Some cones, such as those on the

T-2 tankers, are made in halves and these joints are not tight. If no provision

has been made for filing the

cone after assembly, the tendency is not to put enough tallow in the cone as it

squeezes out on the operator and is messy when the cone is being bolted in

place. If the cone is filled after it is in place, care must be taken to see that

it is properly vented so that no air pockets will be formed and It the weather

is cold there is always the possibility of the warm tallow solidifying when it

strikes the cold shaft and nut thus also leaving void spaces.

It is, however, good practice to fill the

cone with tallow as it serves to protect the steel shaft and nut from salt

water corrosion and electrolytic action from the bronze propeller as well as to

help exclude salt water from the more critical parts of the assembly.

In view of the above we do not feel it is of vital importance whether the cone is filled with

tallow before assembly or after assembly. It is felt, however, that proper

packing of the recess under the propeller nut shouted be considered the primary

means for preventing water from reaching the forward end of the assembly along the top of

the key.

The other major source of difficulty in securing a

watertight assembly seems to be the installation of the rubber sealing ring at

the forward end of the

propeller.

h. A seamless soft rubber ring of circular

cross section should be used. If a seamless ring of the proper size is not

available the joint should be carefully scarfed and vulcanized in order to

ensure tightness. A number of cases of defective joints have been reported.

A hard rubber ring shall never be used nor

shall a ring having a square or rectangular cross section.

If natural gum rubber is used it is

necessary to prevent it from coming into contact with oil or grease as these

cause natural rubber to become “tacky” and lose its springiness. If “neoprene”,

or other oil resistant synthetic rubber, is used this precaution is not

necessary. However, it is not desirable to smear the ring with red lead or

other material as is sometimes done. A previously used ring which has lost its resilience

shall not be refitted.

When an externally fitted packing gland is

used at the forward end of the propeller there is believed to be no particular

difficulty in making a proper installation except for the type of soft rubber

ring. The space between the end of the

shaft liner and the bottom of the

propeller hub counterbore, however, must be filled either with red lead or

equivalent, or one of the petroleum products previously mentioned or by

installing another round soft rubber ring in this space.

i. When red lead or one of the other suitable compounds is used for filling the space in the forward counterbore the arrangements must be such that alt moist salt air will be excluded. In order to accomplish this is customary to drill at least two holes through the hub 180º apart. It is believed desirable to locate the filling hole directly over the keyway in order to insure that this vital spot will be solidly packed.

j. When a round soft rubber ring, as outlined in 8, is fitted in this space it is essential that the bottom of the counterbore always be smooth and flush against the rubber sealing ring. The key should be shortened if necessary so that it will not extend beyond the end of the keyway in the hub. If the key is short, a filler piece should be fitted in the space. The rubber ring shall never be cut back to clear the end of a protruding key.

i. When red lead or one of the other suitable compounds is used for filling the space in the forward counterbore the arrangements must be such that alt moist salt air will be excluded. In order to accomplish this is customary to drill at least two holes through the hub 180º apart. It is believed desirable to locate the filling hole directly over the keyway in order to insure that this vital spot will be solidly packed.

j. When a round soft rubber ring, as outlined in 8, is fitted in this space it is essential that the bottom of the counterbore always be smooth and flush against the rubber sealing ring. The key should be shortened if necessary so that it will not extend beyond the end of the keyway in the hub. If the key is short, a filler piece should be fitted in the space. The rubber ring shall never be cut back to clear the end of a protruding key.

When an internal sealing ring is used it is

also desirable to have the propeller counterbore diameter about 1/2 inch larger

than the outside diameter of the shaft liner and the rubber ring shall be large

enough to squeeze into the 1/4 inch clearance. This arrangement prevents the

rubber from becoming “column

bound” and gives assurance through visual examination that a good seal has been

obtained.

k. In order to exclude all salt air and to

prevent as far as practicable

any seepage of moisture through possible slight porosity in the casting, the

cored recess in the propeller hub should be packed with warm tallow or

petroleum compound before assembly. If tapped holes are revived an additional

amount sufficient to completely fill the recess shall be added after assembly.

l. Before the wheel is put on care should

be taken to clear out all tapped holes which are to be used for venting and

pumping up after assembly. Care must also be taken to see that all such holes have

been properly closed with screw plugs after assembly has been completed.

The use of Esso Rust Ban #324, Gulf No-Rust

#1 or #3, and similar corrosion inhibiting compounds instead of red lead putty

or tallow has been approved by Flag Administration or Class Society and has been used by several of the oil companies on

their tankers. The experience with these materials is limited but they are

believed to be well suited to the purpose. Red lead putty is not entirely

satisfactory for pumping up void spaces because it tends to harden and crack in

service.

In order to reduce as far as possible shaft

failures which may be the result of improperly installed propellers, it is

requested that the contents of this attachment be discussed with all shipyards,

ship repair yards and Owners’ representatives in your area. Additional

uncontrolled copies of this attachment may be obtained for the use of the

shipyard and other interested persons if desired.

We believe that the procedures outlined are

representative of good practice and that if they be rigidly adhered to and care

be taken with all other details of the assembly there should be an appreciable

reduction, within the next few years, of the number of shaft failures being

experienced.

2. Stress

concentrations in propeller assembles

Most of the cracks in the shafting occurred

near the end of the keyway, in way of the forward end at the fit of the

propeller hub on the shaft or in way of the end of the fit of the shaft liner.

The suggestions given below might prove effective in helping to alleviate this

condition should any of the Owners wish to incorporate them on their ships.

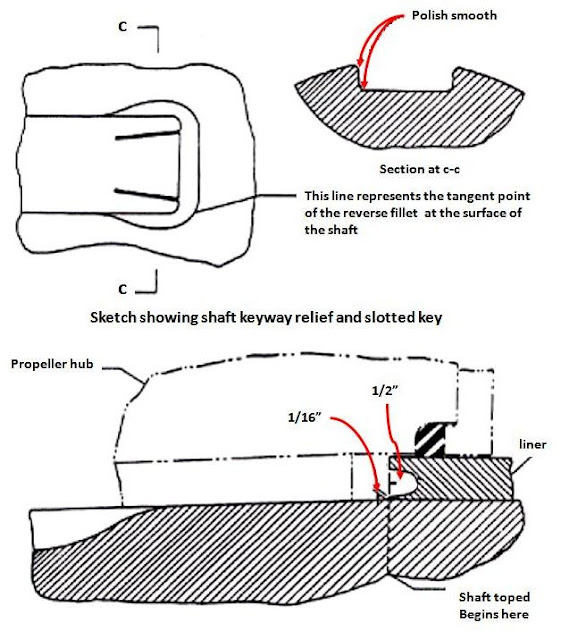

The suggestions are indicated on the

attached sketches and as follows:

a. In most assemblies the keyway in the

shaft runs out approximately at the bottom of the propeller hub counterbore of

the propeller hub. Since both the keyway itself and the edge of a press fit cause

stress concentrations, it was suggested that the stress concentration at this location

might be reduced by stopping the keyway several inches short of the bottom of

the hub counterbore.

b. In order to further reduce the stress concentration

al the end of the keyway smooth fillets should be provided at the bottom comers

of the keyway and at the forward end reverse fillets be used at the top of the

keyway to blend it gradually and smoothly into the contour of the shaft; this

would make a “spoon-shaped” ending to the keyway. It was also suggested that

two saw slots or a “fish-tail” slot be provided in the end of the key itself in

order to avoid a sudden change in loading at the end of the key.

c. A considerable amount of research had

been carried out on the problem of fatigue of shafts at fitted members. One

simple method found for reducing the stress concentration in such locations as

at the end of the shaft liner and at the edge at the propeller hub fit is to

provide hoop-stress relief grooves in the end of the liner and in the forward

face of the propeller hub at the bottom of the counterbore as shown on the attached

sketch. Some indication of the effectiveness of these grooves in reducing

stress concentrations is given by the accompanying photoelastic studies which

have been reproduced from a paper entitled “Fatigue

of Shafts at Fitted Members with a Related Photoelastic Analysis”, by

Peterson and Wahl, published in the ASME Transactions for 1935.

|

| Sketch showing suggested hoop stress relief for propeller hub and shaft liner. |

NOTE: it is important that the stress relief grooves be at least 1/2 inch deep and that the thickness of the lip at the edge be held at 1/16 inch. The side of the stress relief groove adjacent to the shaft should have an easy slope as shown to provide effective relief over a distance of at least 1/4 inch from the edge of the fit.